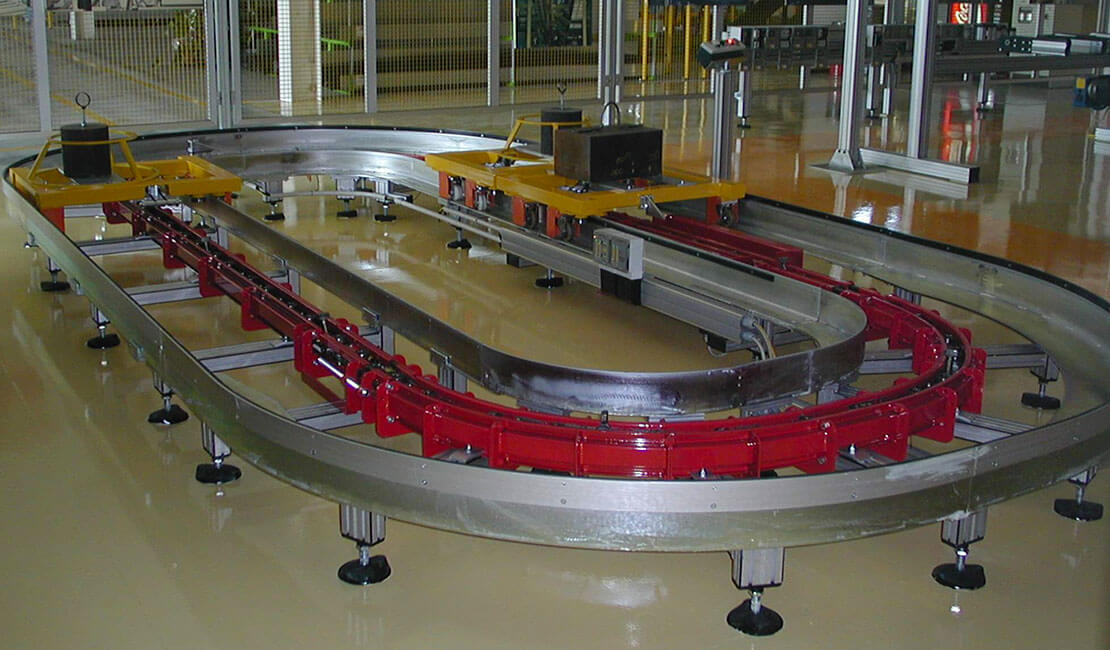

Overhead monorail conveyor systems

We build overhead monorail conveyor systems perfect for storage

The overhead monorail and ground conveyors solve the simplest problems of transportation and storage connecting two or more working areas operating at the same rates.

The conveyor can operate step-by-step or have a continuous flow. Its speed can be fixed or variable and the range can be anywhere between 0.1 m/min and 30 m/min. The main features of overhead monorail conveyor systems are:

- possibility of working in particularly harsh environments, for example where there is a lot of dust and/or high-temperature ovens, thanks to the use of special materials and bearings

- operation without any automatic tensioning system, thanks to the chain working in compression

- very low friction and limited wear and tear of the components thanks to the uniform distribution of loads between chain and rails

- possibility of horizontal bends at angles from a minimum of 5° to a maximum of 270° and vertical bends at angles from a minimum of 5° to a maximum of 45°. Indeed, the chain is articulated on two orthogonal floors

- bends with minimum radius and no need of idler wheels depending on the characteristics of a line, the load capacity can range from 80 daN (with single support) to a maximum of 160 daN (with double support).

Additional features

- overhead conveyors are anchored to ceiling- or floor-mounted suspensions

- ground conveyors rest on the floor or are buried underground and protected by metal sheets.

Technical Documentation

Product Data Sheet – Monorail Overhead Conveyor

Info

Contact us for a solution tailored to your company's needs.

Do you need assistance or have any questions? Don't hesitate to contact us! We are here to help you and provide you with all the information you need.