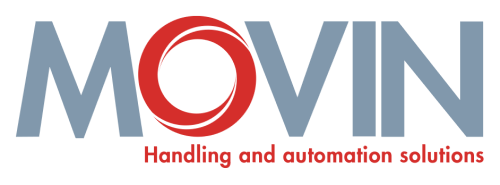

Power & free overhead conveyor system

Our overhead double-rail conveyor systems: the perfect solution to complex handling problems

The double rail conveyors are systems that allow solving the most complex handling problems, such as the interconnection of two or more working areas working at different rates.

The virtually unlimited flexibility of the double rail conveyors allows to manage the interconnections by means of specific functions like the following:

- transfer of goods per units or batches based on the different working areas, with an automatic deviation of unrequired loads and independence of each load

- different capacities (rates) in different areas of the plant

- loads accumulating (storage) in an area of the plant not affected by the production workflows

- static stacks

- dynamic stacks

- transfer of goods at specific rates in relation to a part of the plant

- transfer of goods at specific speeds in relation to a part of the plant

- perfect synchronization between the different movements of the loads

- loads sorting through encryption systems

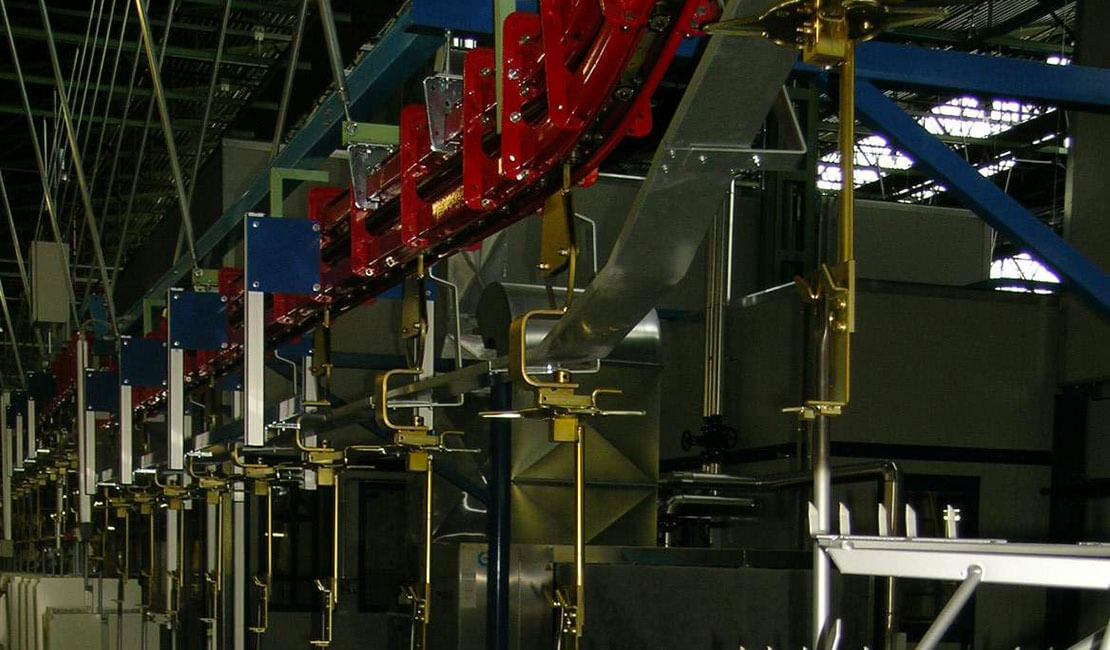

- line changes (divergences and convergences)

- recycling

Additional features

- possibility of working in particularly harsh environments, thanks to the use of special materials and bearings

- possibility of fast and low chains in the same system: fast chains for a quick sorting; slow chains for close-up operations

- possibility of different types of stacks in the same plant

- optimization of the spaces. Operation without any automatic chain tensioning system, thanks to the chain working in compression

- possibility of horizontal bends at angles from a minimum of 5° to a maximum of 270° and vertical bends at angles from a minimum of 5° to a maximum of 45°. This is because the chain is articulated on two orthogonal floors

- possibility of bends with minimum radius and no need of idler wheels.

Technical Documentation

Product Data Sheet – Double Rail Overhead Conveyor

Info

Contact us for a solution tailored to your company's needs.

Do you need assistance or have any questions? Don't hesitate to contact us! We are here to help you and provide you with all the information you need.